120 seconds to understand

Two minutes to learn the basic elements of what Technoprobe has been producing in the last 25 years

Key elements

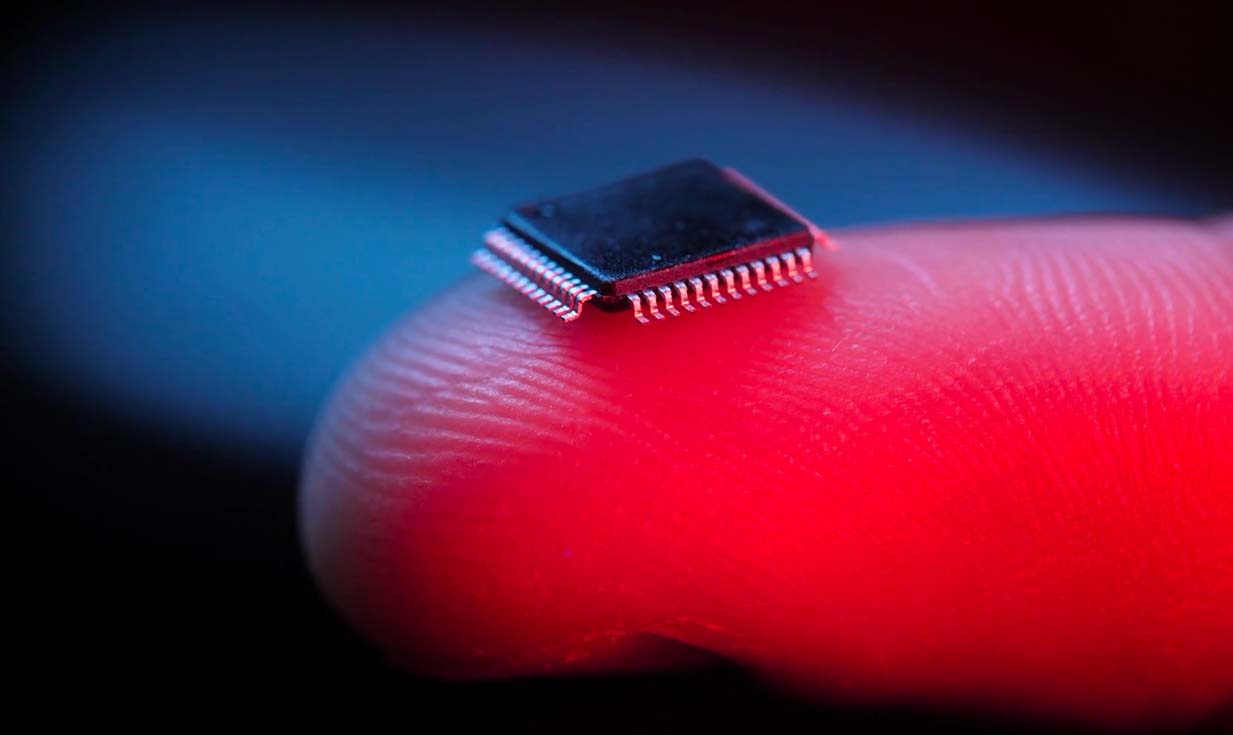

Chips

Chips are in so many objects around us, from smartphones to credit cards, from cars to medical instruments.

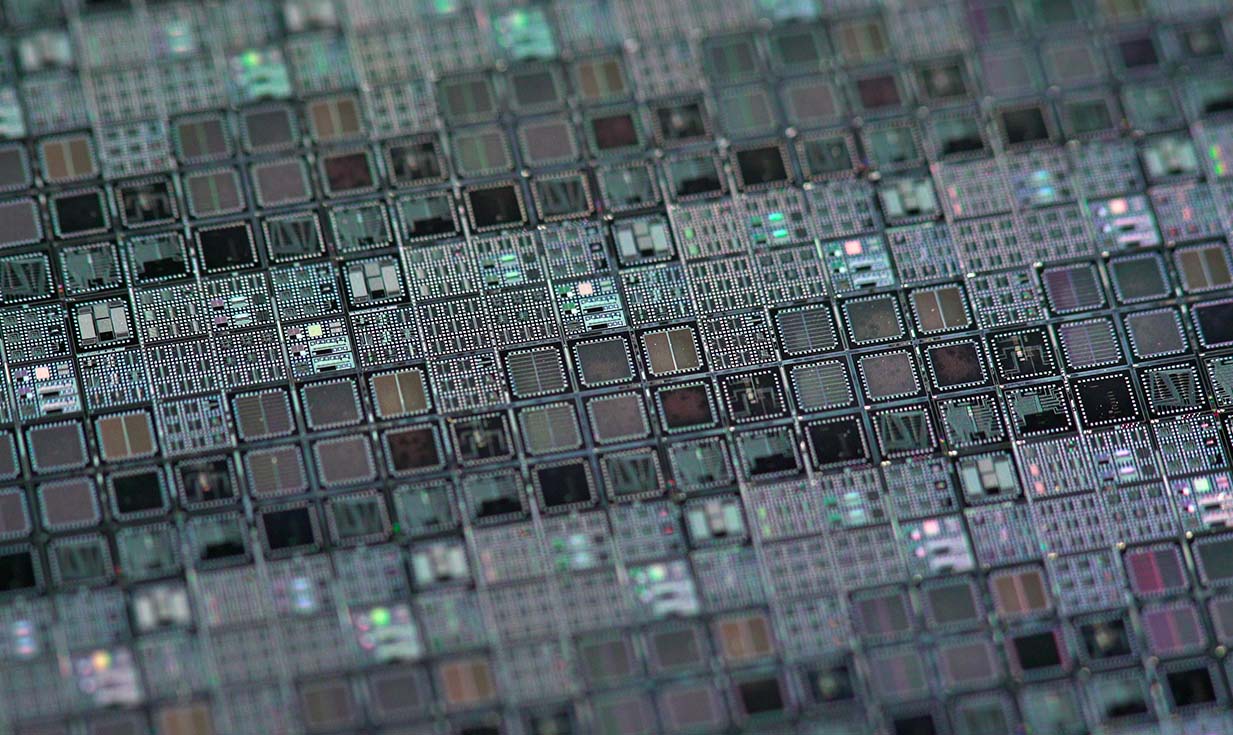

Wafer

Chips are made on a wafer, a thin slice of semiconductor material (typically silicon).

From the wafer to the final device

Once made on the wafer, the chips are separated, put into a package and then mounted on the final device, where they carry out their work.

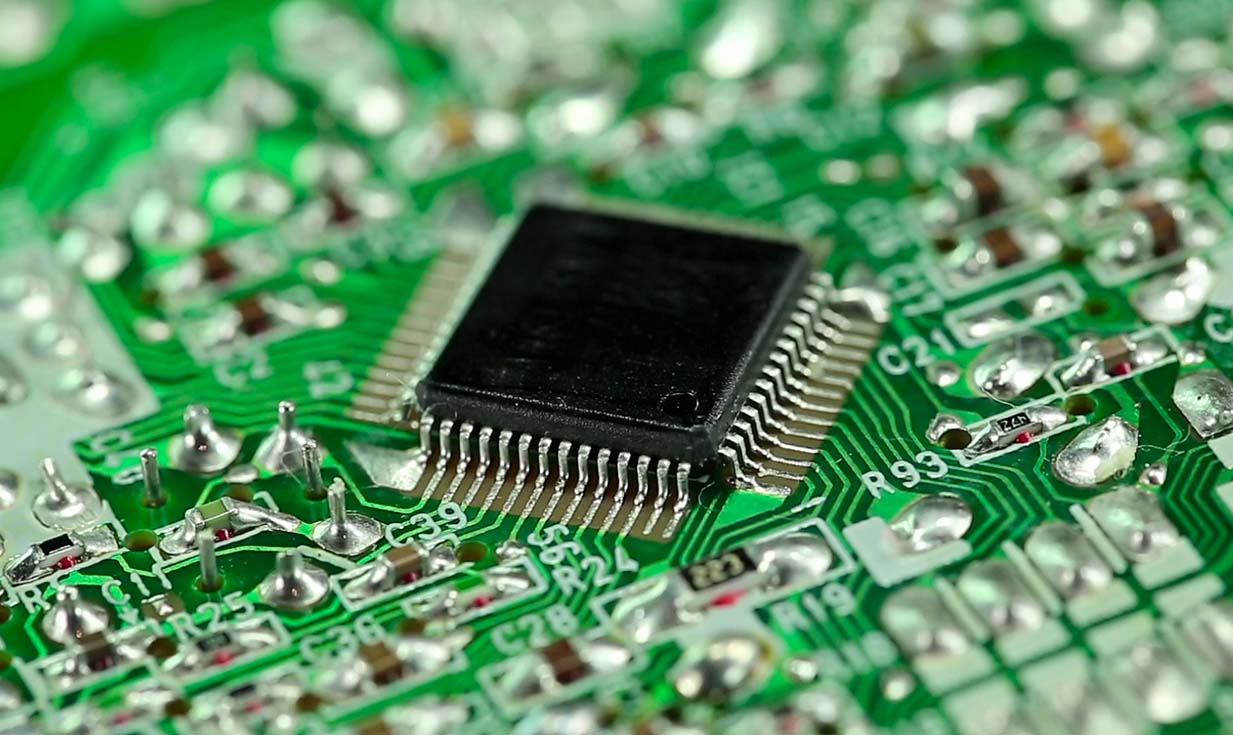

Attention!

A chip must be tested to make sure it works.

Finding out that a chip doesn’t work only after it has been put into its package would be a big loss in many ways.

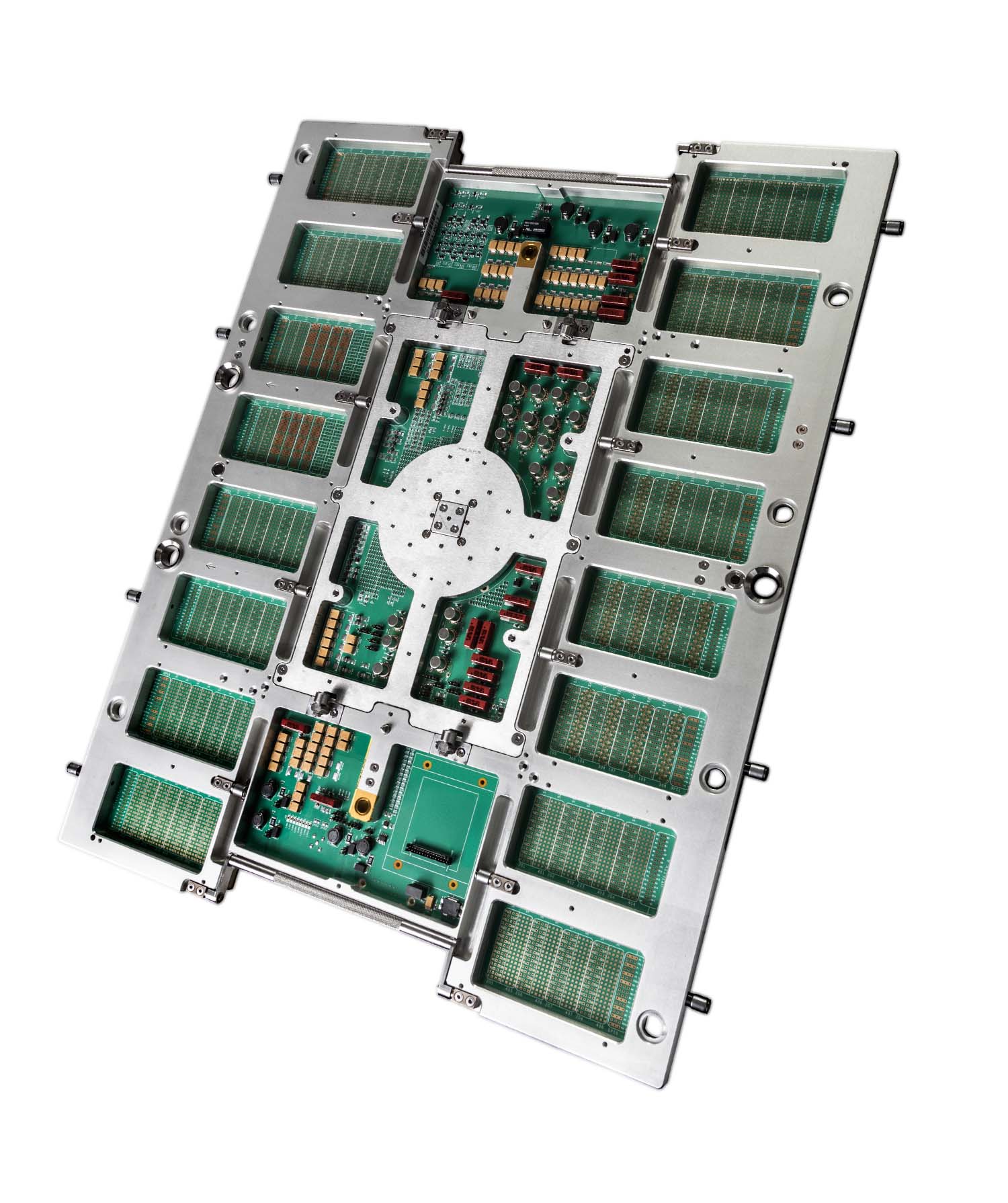

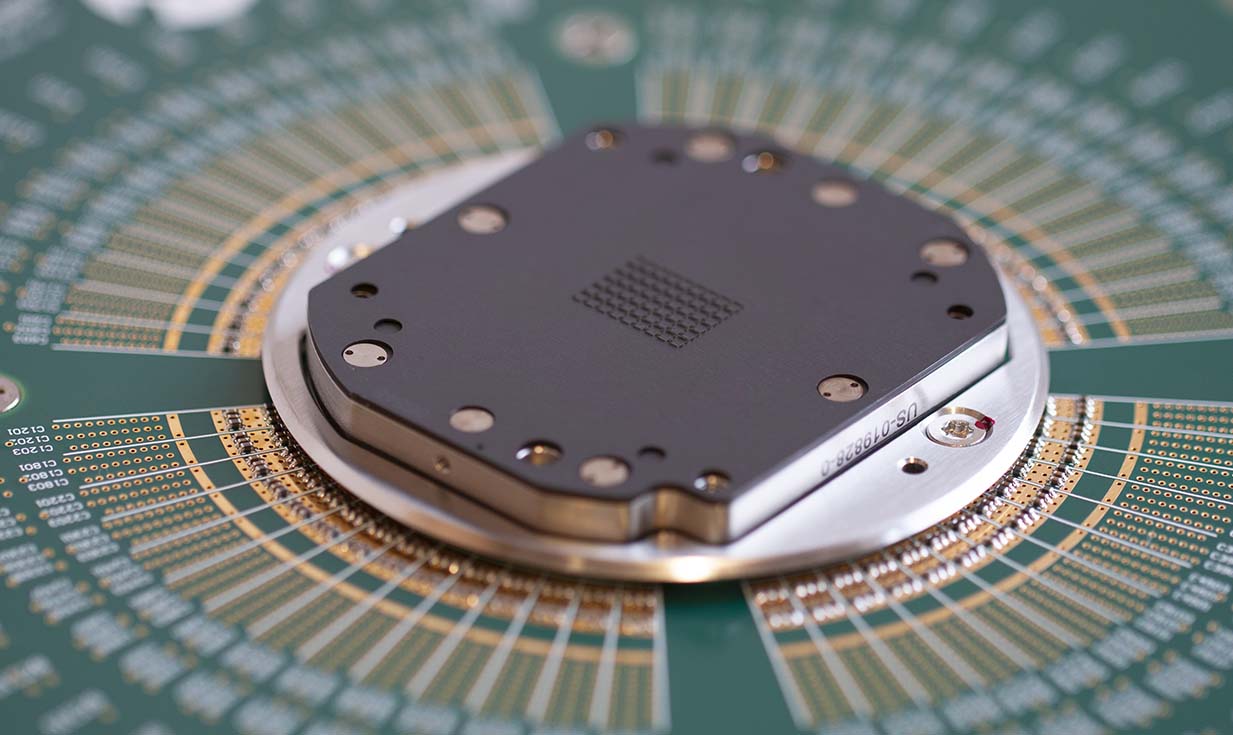

Probe cards

This is where probe cards come into play.

A probe card is an electromechanical interface that allows testing the functioning of a chip when it is still on the wafer or before it is individually packaged.

How does it do this?

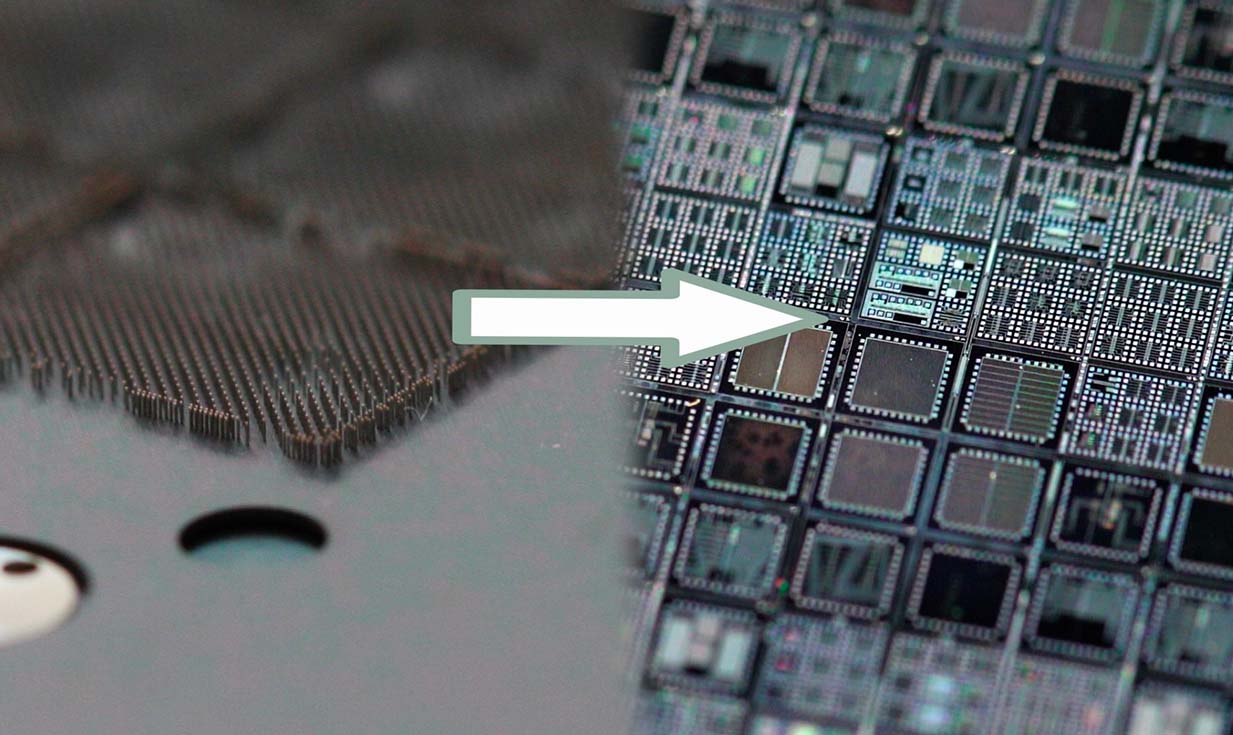

Probes make contact with the chips

The probe card makes contact with the pads or bumps of the chips.

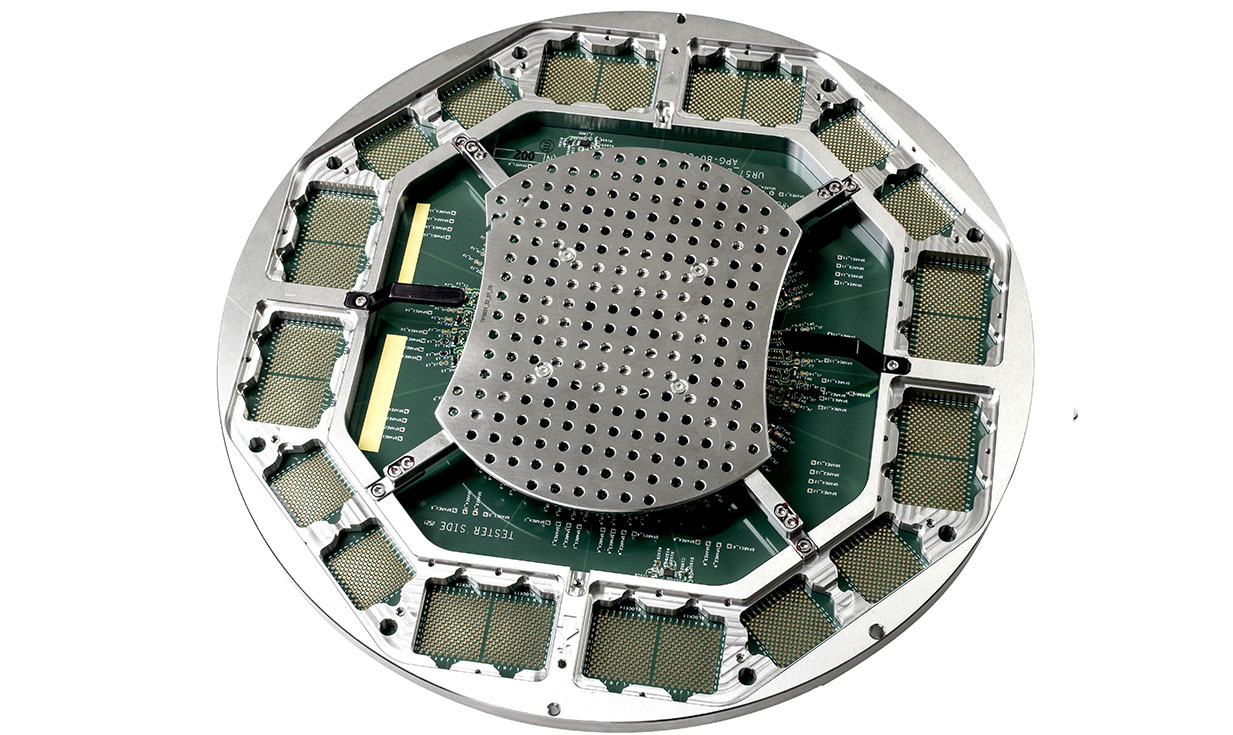

From the probe card to the tester

Once it has made contact with the chip, the probe card connects it electrically to the tester which checks the functionality of the chip.

Custom made

Each probe card is custom made for the chip to be tested.

A huge, tiny world

They are highly technological devices. Probe cards can have more than 50,000 contacts and the distance between them can be as small as 40µm (4 hundredths of a millimetre).